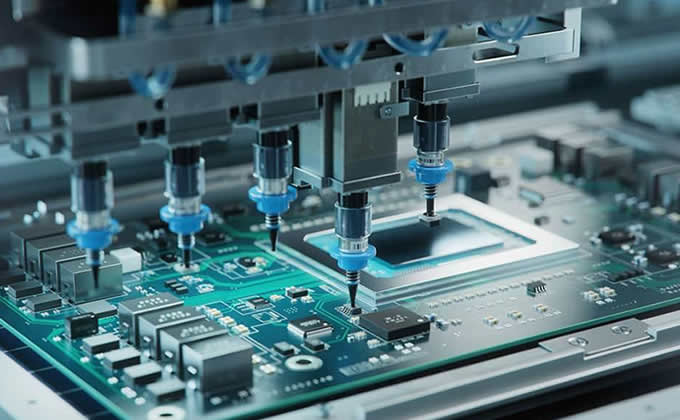

Turnkey Production

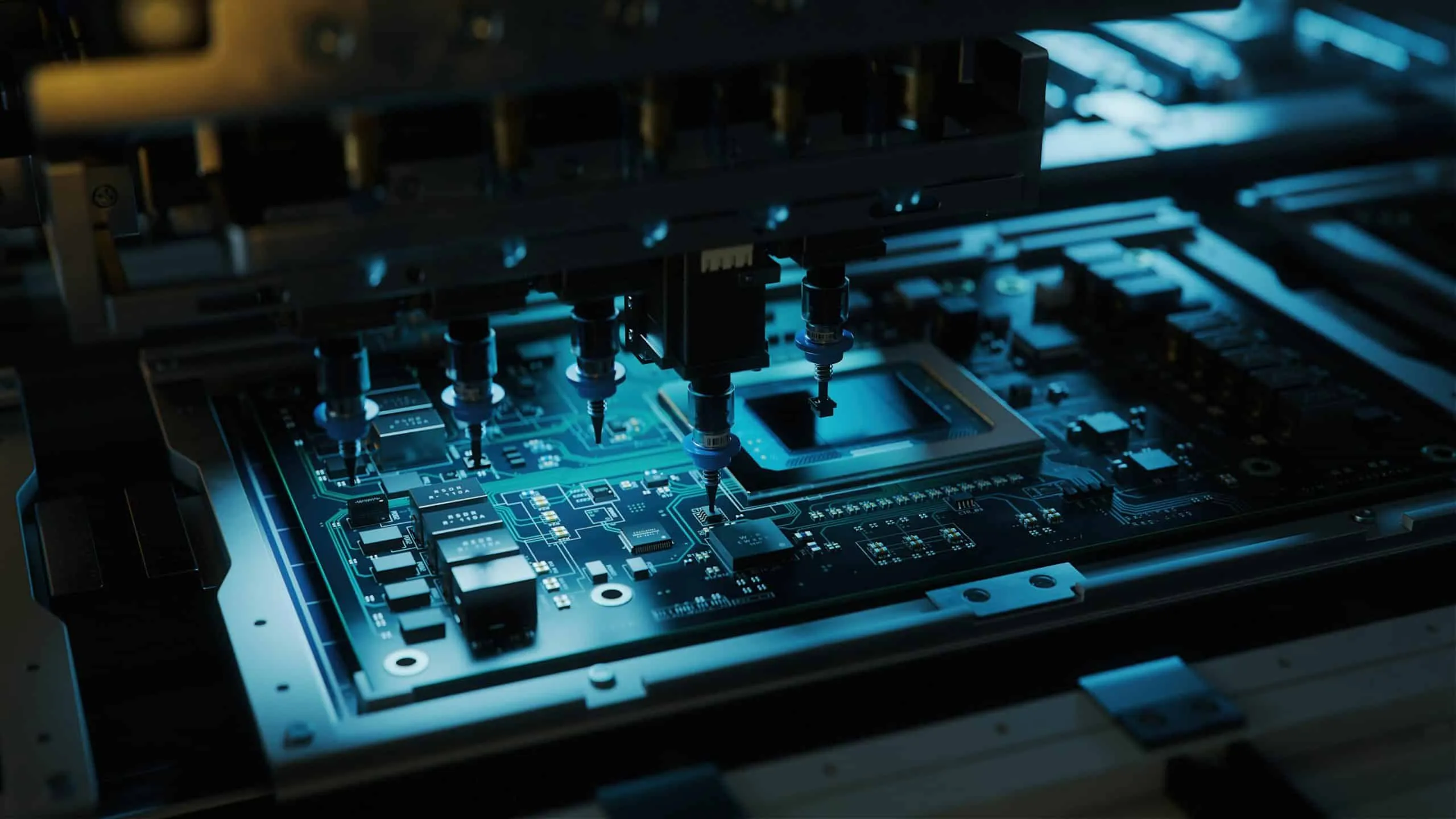

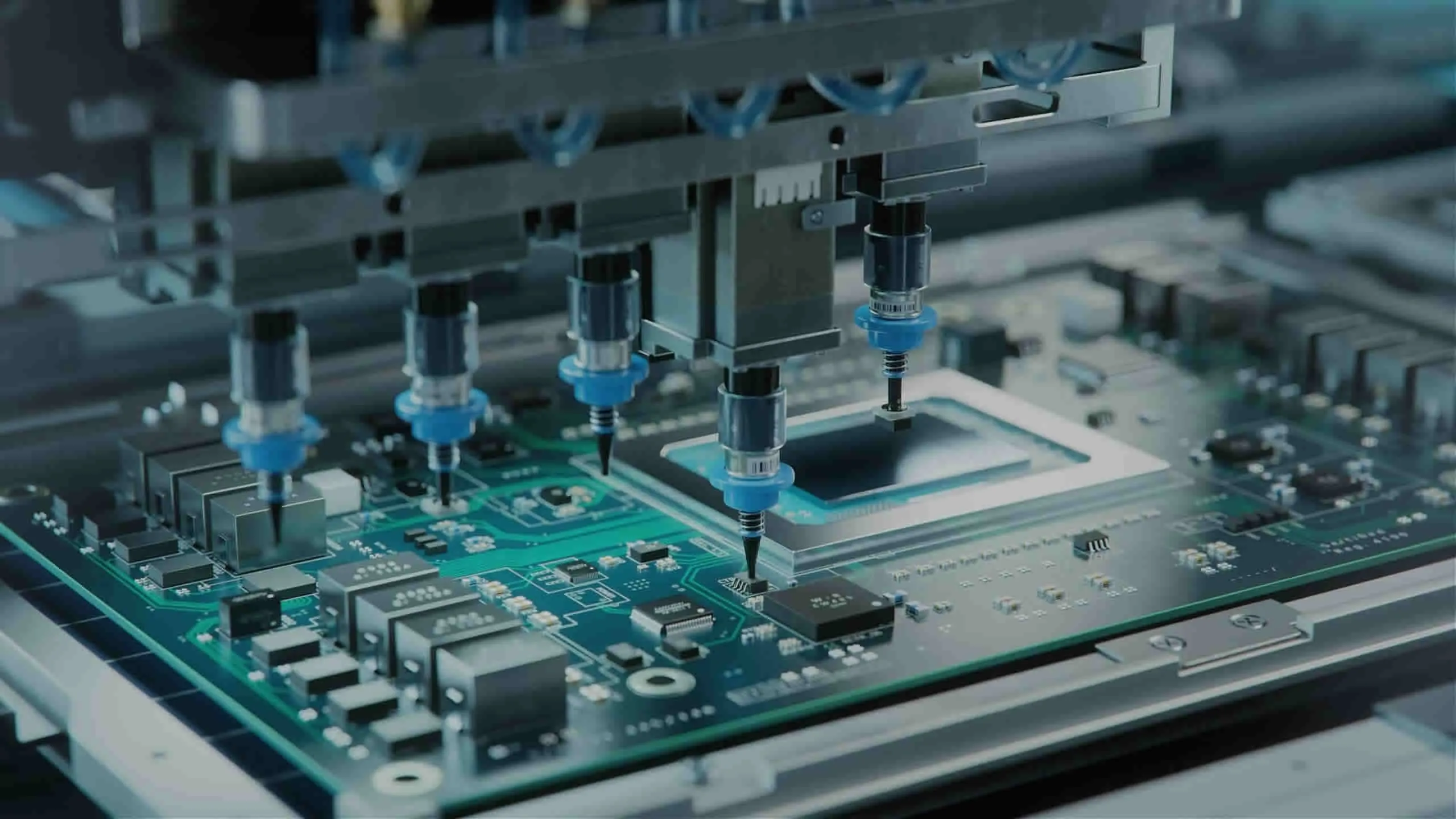

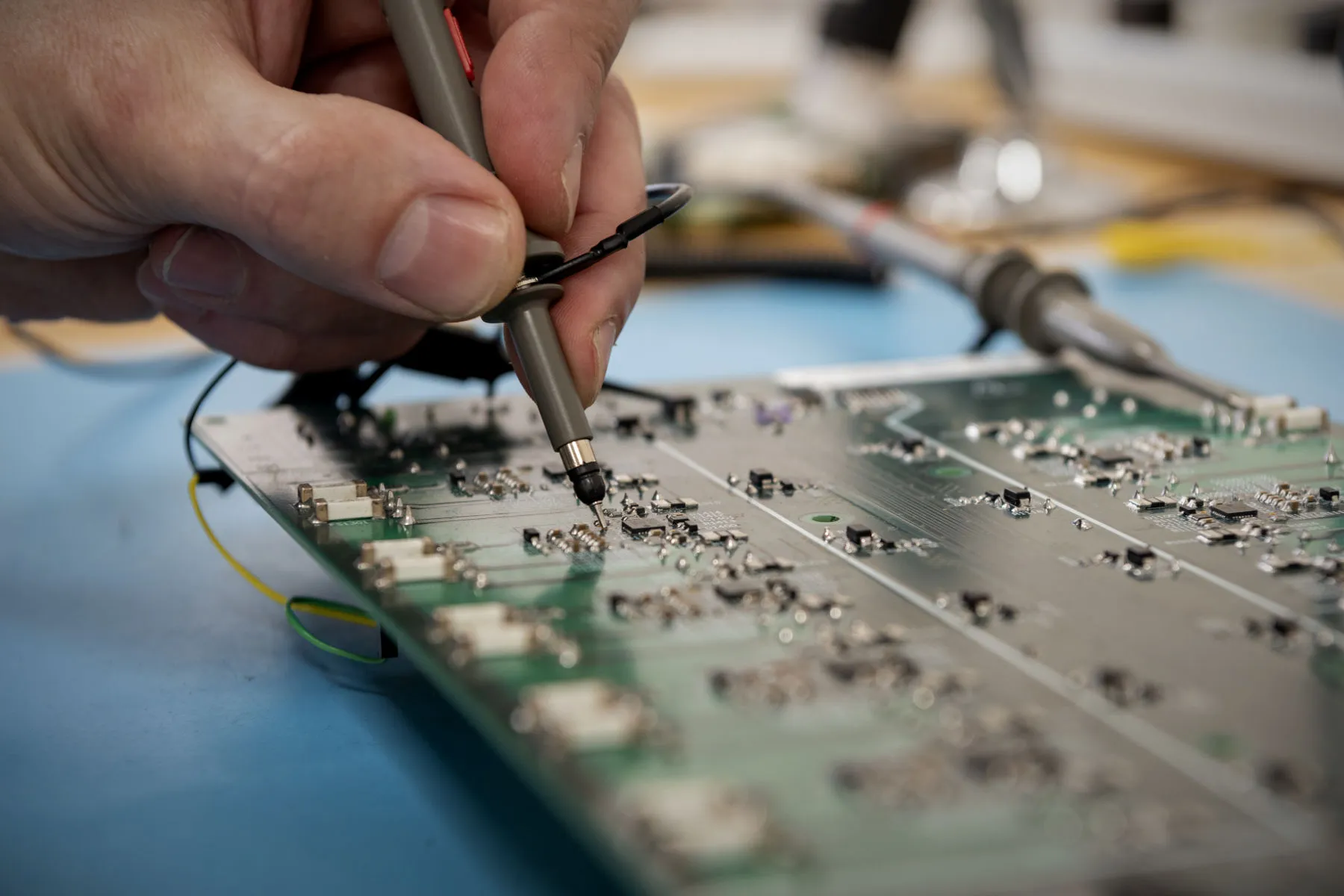

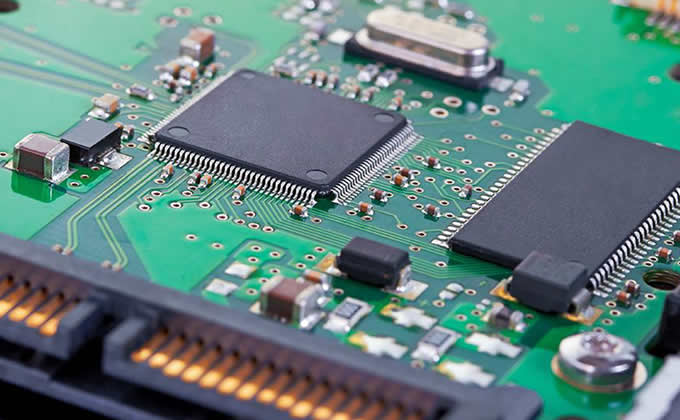

PCB Assembly

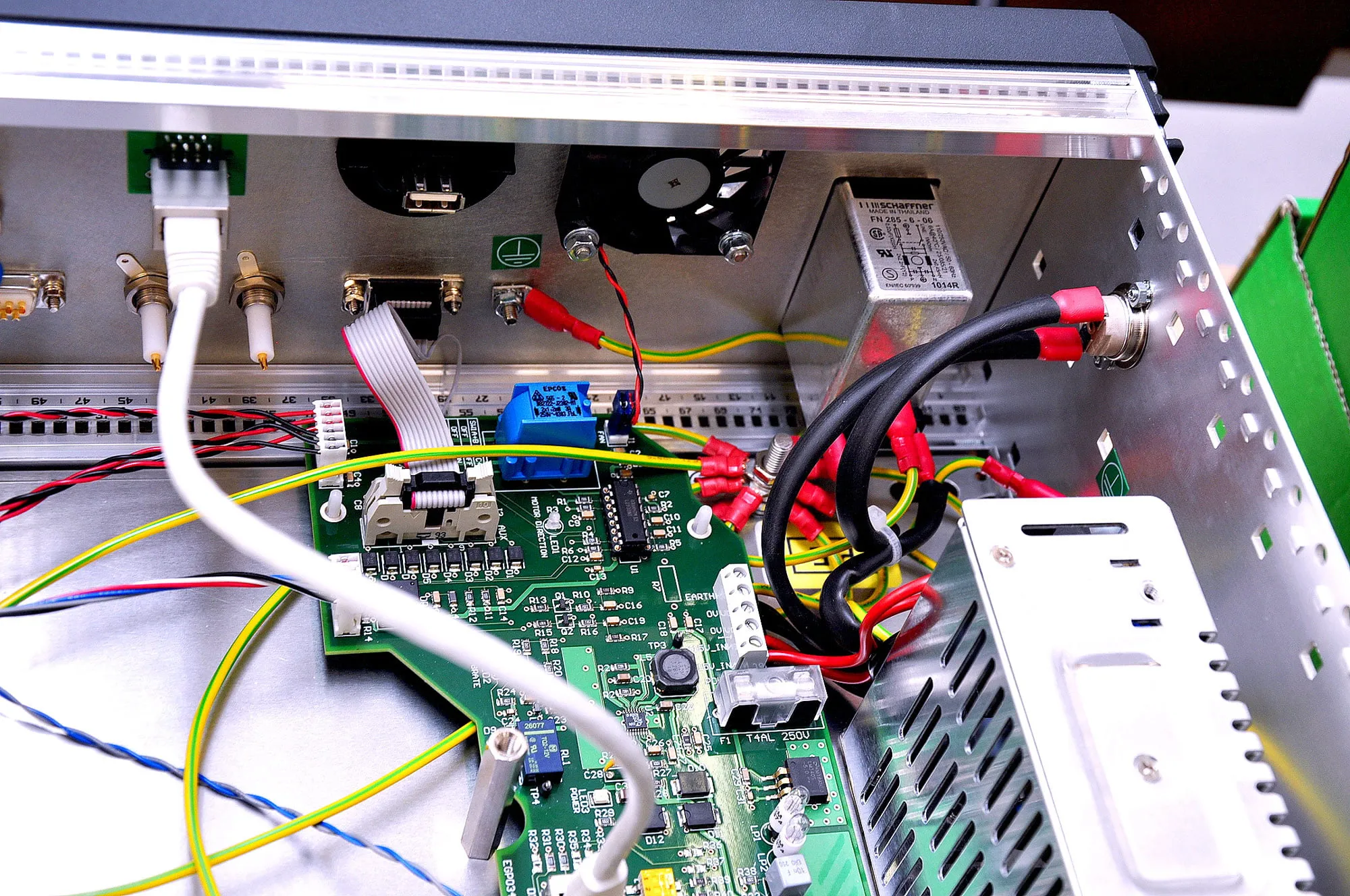

Boxe Build Assembly

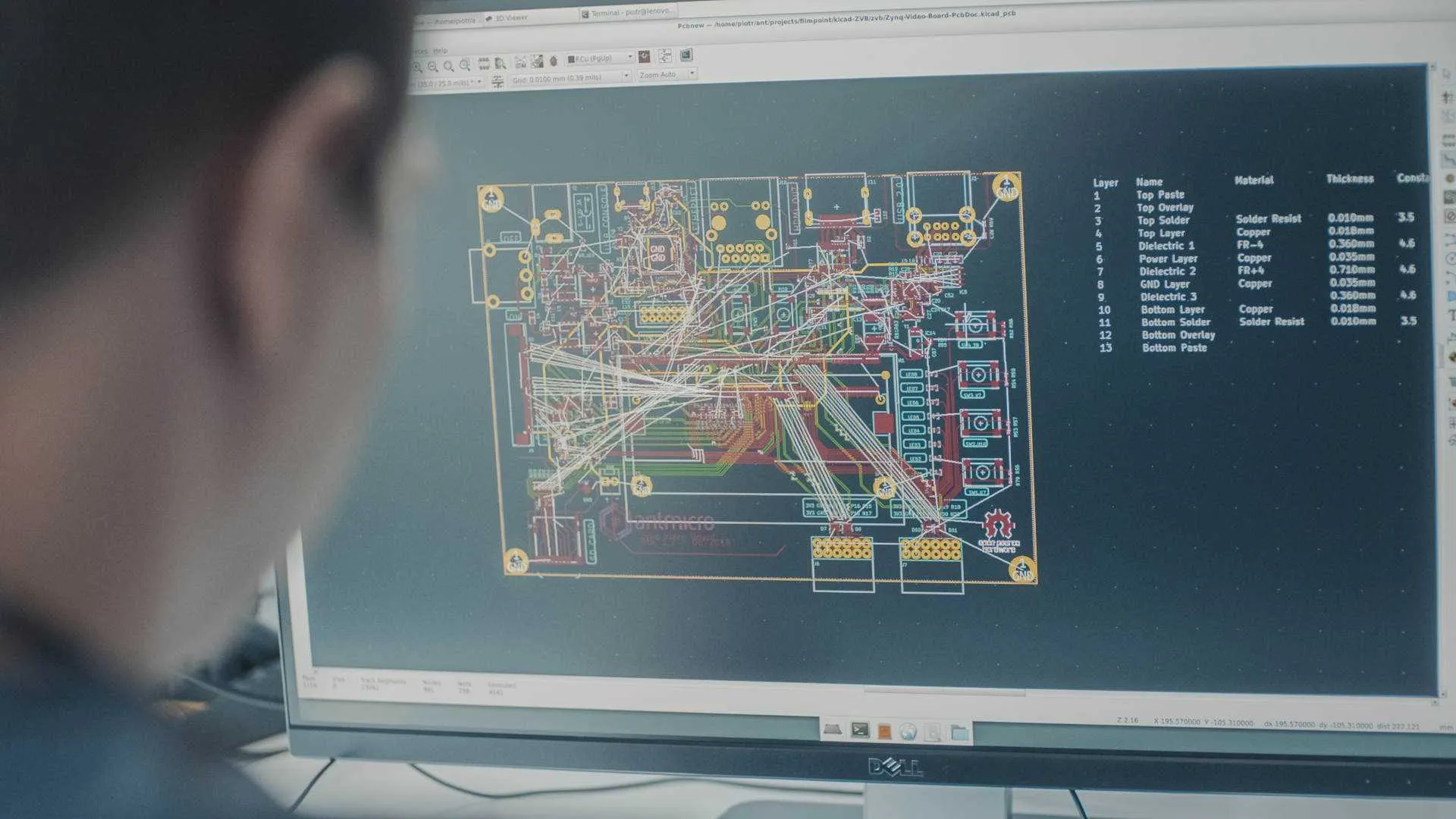

Reverse Engeering and Design

Schematic

PCB Layout

Mechanical

Development

Firmware

Software

PCB Assembly Services CANADA

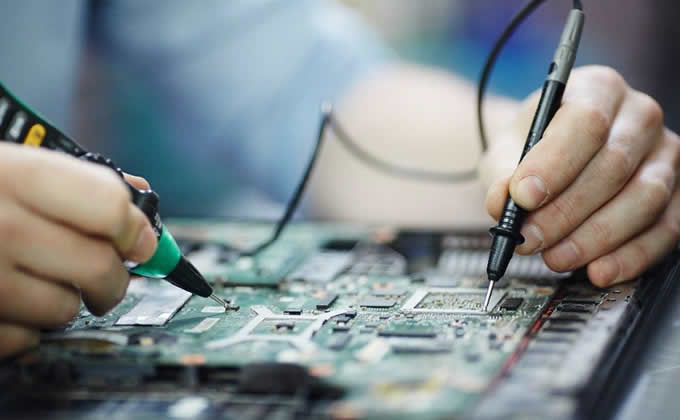

Nano-Tronic company, with its past experience and strong supply chain, provides PCBA (PCB Assembly) services to many sectors. It also provides services in electronic design, software and mechanical design with its professional expert engineers. Nano-Tronic is a corporate limited company based in Canada.

Generally, you can find that the PCB circuit is characterized by the soldered conducting components. The companies which offer the PCB assembly services put the effort in this particular area.

Services We Offer